Gasless MIG Wire & Self-Shielded Flux Core

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

Gasless MIG Wire & Self-Shielded Flux Core

Experience the freedom of welding anywhere with ARCCAPTAIN's premium Gasless MIG Wire (E71T-GS). Designed for superior arc stability and low spatter, our self-shielded flux core wire eliminates the need for heavy gas cylinders.

Whether you are repairing fences in the wind, welding dirty farm equipment, or fabricating structural steel, our wire delivers deep penetration and professional results on standard 110V and 220V MIG welders.

Why Choose ARCCAPTAIN Gasless Welding Wire?

Not all welding wire is created equal. Our E71T-GS Flux Core Wire is engineered specifically for welders who need reliability in tough conditions.

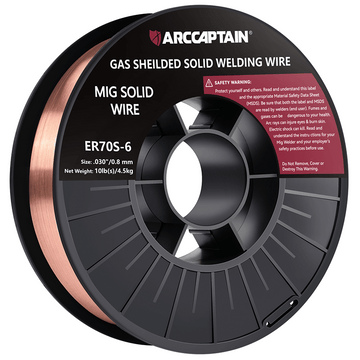

Unlike solid wire (ER70S-6) which creates porosity if the gas blows away, our wire generates its own protective shield directly at the arc.

- Outdoor Ready: Perfect for windy conditions where shielding gas blows away.

- Forgiving on Metal: Excellent performance on rusty, painted, or galvanized steel.

- Portability: No gas bottle means a lighter, more portable welder setup.

- TÜV Certified: Tested rigorously for consistent feedability and strength.

While you're gearing up, remember to explore our comprehensive range of welding protective gear, rugged welding gloves, and innovative auto-darkening welding helmets, guaranteeing you're completely geared up for any welding job, gasless or otherwise.

How to Setup and Use Gasless MIG Wire

1. Gasless MIG Polarity: DCEN (Straight Polarity)

Crucial Setup Step: When using gasless flux core wire, you must switch your welder's polarity to DCEN (Direct Current Electrode Negative).

- Torch/Gun: Connect to Negative (-) Terminal.

- Ground Clamp: Connect to Positive (+) Terminal.

Note: If you use the wrong polarity (DCEP), your weld will be piled up, have excessive spatter, and weak penetration.

2. Recommended Settings (Voltage & Wire Speed)

Use these starting parameters for ARCCAPTAIN E71T-GS wire. Fine-tune based on your specific machine's behavior.

| Metal Thickness | Wire Diameter | Voltage (Volts) | Wire Speed (IPM) |

|---|---|---|---|

| 22 Gauge (0.8mm) | .030" (0.8mm) | 14.5 - 15.5 V | 160 - 180 IPM |

| 1/8" (3.2mm) | .030" (0.8mm) | 16.5 - 18.0 V | 240 - 260 IPM |

| 1/8" (3.2mm) | .035" (0.9mm) | 17.0 - 18.5 V | 200 - 220 IPM |

| 1/4" (6.4mm) | .035" (0.9mm) | 19.0 - 21.0 V | 320 - 340 IPM |

3. Technique: Push or Pull?

For gasless MIG welding, the golden rule is: "If there's slag, you drag." Always use a Drag (Pull) technique. Tilt your torch back 10-15 degrees and pull the weld puddle along the joint.

This prevents slag from getting trapped inside the molten metal, ensuring a solid, crack-free weld.

Solid Wire vs. Gasless Flux Core: Which Do You Need?

| Feature | Gasless Flux Core (E71T-GS) | Solid Wire (ER70S-6) |

|---|---|---|

| Shielding Gas | None Required (Self-Shielding) | Required (C25 or 100% CO2) |

| Wind Resistance | Excellent (High) | Poor (Gas blows away) |

| Metal Condition | Handles rust, paint, dirt well | Requires perfectly clean metal |

| Spatter Level | Moderate | Low / Very Clean |

| Best Use | Outdoor, Farm, Fences, Repairs | Indoor Shop, Auto Body, Aesthetics |

Looking for Solid Wire? If you are welding indoors on clean automotive sheet metal, check out our Solid MIG Wire Collection (ER70S-6) which requires a gas cylinder.

Recommended Articles To Read

- How To Wear a Welding Cap for Safety

- What You Need to Start Welding from Home: Complete Guide

- Tips for Welding Sheet Metal With MIG or TIG

Frequently Asked Questions About No-Gas Welding

Can I use gasless wire on a regular MIG welder?

Yes, as long as your MIG welder allows you to change polarity. Most modern MIG machines, including the ARCCAPTAIN MIG130 and MIG200, have easily swappable terminals on the front or inside the cabinet to switch to DCEN (Electrode Negative) for flux core wire.

Is gasless MIG wire as strong as solid wire?

For most general repairs and structural steel applications, yes. E71T-GS has a tensile strength of roughly 71,000 PSI, which is comparable to standard solid wire. It actually provides deeper penetration than solid wire, making it excellent for thicker joints.

What is the difference between .030" and .035" wire?

.030" (0.8mm) is best for thinner metals (sheet metal up to 1/8") and prevents burn-through. .035" (0.9mm) carries more amperage and deposits metal faster, making it ideal for 1/8" up to 1/4" steel plating or structural tubes.