Arccaptain AC DC TIG200P Multi Process Pulse TIG Aluminum Welder

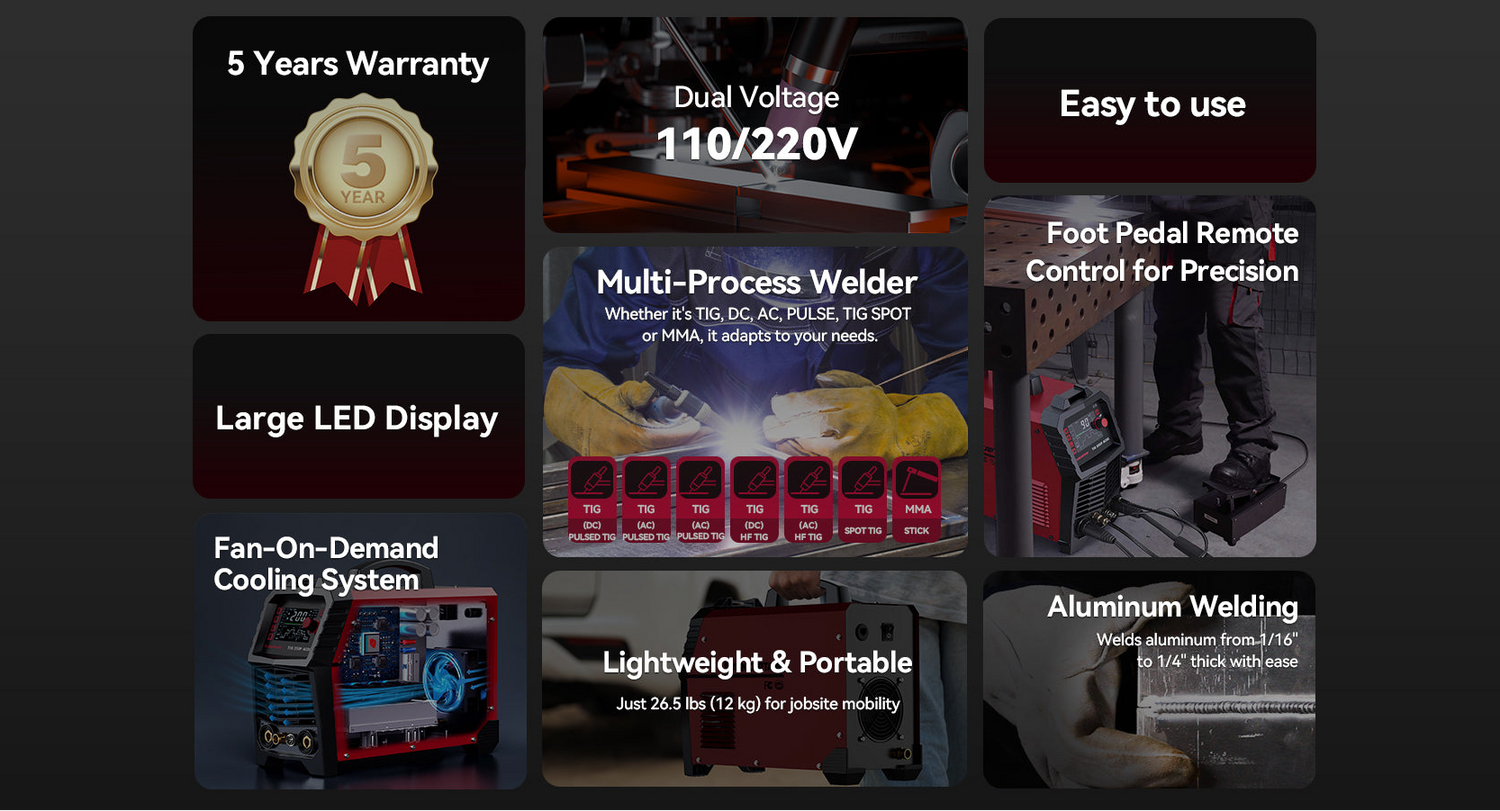

- Outstanding Aluminum Welding Power: Welds aluminum from 1/16" to 1/4" thick with ease—perfect for all your aluminum projects.

- Versatile Multi-Process Capability: Whether it's TIG, DC, AC, PULSE, or MMA, this welder adapts to your needs.

- Advanced ARC ignition Technology: The system ensures superior welding performance and precision. increases the arc ignition success rate by 36%.

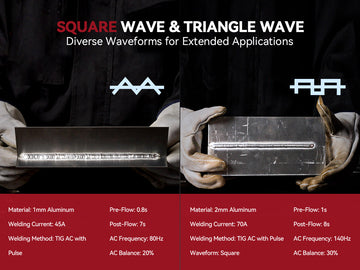

- Comprehensive AC & DC Modes: Includes AC Square, AC Triangular, AC Pulse Square, AC Pulse Triangular, DC Pulse, and MMA for diverse welding applications.

- Industry-leading Large Display: Effortlessly control your welding parameters with our user-friendly control panel.

- Foot Pedal Control Support: Enhance your welding precision with convenient foot pedal control.

- Lightweight and Portable: At just 26.5 Lbs, this welder combines power with portability, perfect for both workshop and field use.

- High-Quality TIG Torch: Comes with a WP26 style 35-50 type TIG torch, designed for reliability and ease of use.

- 5-Year Warranty

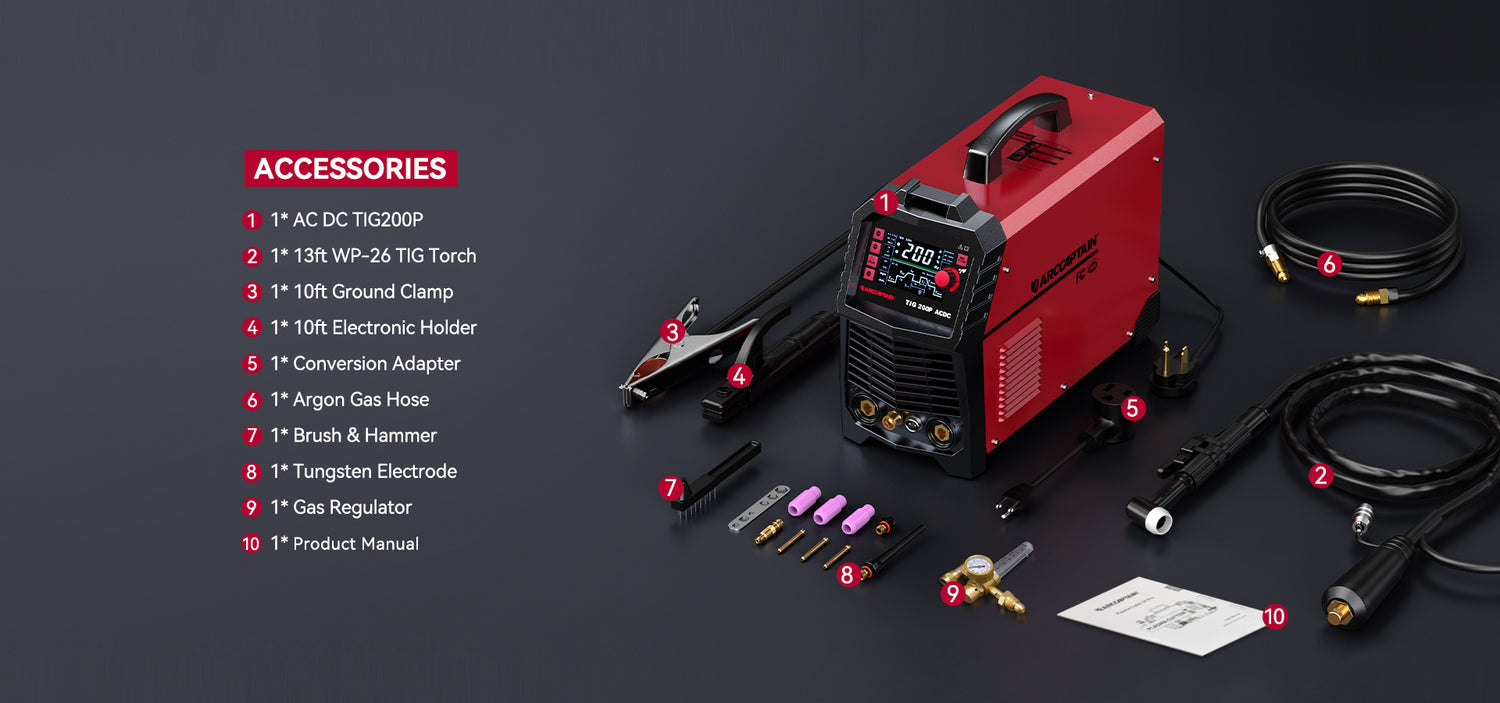

AC DC TIG200P *1

13ft WP-26 TIG Torch *1

10ft Ground Clamp *1

10ft Electronic Holder *1

Conversion Adapter *1

Argon Gas Hose *1

Brush & Hammer *1

Tungsten Electrode *1

Gas Regulator *1

Product Manual *1

-

Estimated Delivery:Feb 21 - Feb 25

-

- Free Fast Shipping

- Experience peace of mind with our trusted logistics services.

The AC/DC TIG 200P welder is a powerful aluminum TIG welding machine that offers welding with TIG AC Square/Triangular/Pulse Square/Pulse Triangular/DC Pulse/DC/STICK methods. It can be used for welding various metals, including aluminum, steel, stainless steel, carbon steel, and copper.

The technology improves arc striking speed, welding efficiency, and results, while the pulse, square, and triangular waveform functions prevent material burning, minimize distortion, and improve bead appearance. The digital control system makes the machine reliable and stable, and the large LED display allows for easy parameter adjustment.

The TIG200P AC DC Pulse Tig Aluminum Welder is lightweight and compact at only 12 kg (26.5lb). Plus, included safety features like VRD, over-current, over-voltage, overload, and over-temperature protection make it user-friendly and reliable.

Moreover, you can choose between 2T/4T/Spot welding TIG torch control and foot pedal remote control methods for a more versatile welding experience. This is a great choice for pro welders!

ARCCAPTAIN TIG200P AC/DC Pulse Welder – Precision Meets Power

Professional-Grade Versatility: Weld aluminum, steel, stainless steel, copper, and more with ease. The TIG200P supports AC/DC TIG (with adjustable square/triangle/pulse waveforms) and Stick welding up to 160A, perfect for delicate projects or heavy-duty repairs.

- Start welding in a flash: arc ignition speeds up to 5x faster (40ms vs. 200ms) with a 99.99% success rate

- Reduced tungsten damage and ultra: stable arc for cleaner, stronger welds

-

Digital control ensures whisper: quiet operation and consistent performance

Smart Waveforms for Flawless Results

- Pulse/Square/Triangle modes prevent burn-through, minimize warping, and create pro-quality bead finishes

- Square wave AC crushes aluminum oxide for cleaner welds and better arc control

Built for Real-World Convenience

- Lightweight & portable: Just 26.5 lbs (12 kg) for jobsite mobility

- Large LED display with intuitive controls: Adjust pre-flow, slope timing, crater fill, and more in seconds

-

Flexible control options: Use the handheld torch (2T/4T/spot modes) or add a foot pedal (sold separately)

Safety You Can Trust

Auto-shutdown protection against overheating, voltage spikes, and overloads. VRD (Voltage Reduction Device) keeps you safe during electrode changes.

|

Project Name |

Unit |

Value |

||

|

Power voltage |

VAC |

AC110V±15% AC220V±15% |

|

|

|

Input frequency |

Hz |

50 |

||

|

Rated input current |

A |

33@TIG 35@MMA |

||

|

Capacity of power supply |

KVA |

6.0@TIG 7.5@MMA |

||

|

Output current range (TIG) |

A |

10~120(110 v) 10~200 (220v) |

|

|

|

Output current range (MMA) |

A |

10~110(110v) 10~160(220v) |

|

|

|

Arc force range |

A |

0~40 |

||

|

Hot start current range |

A |

0~80 |

||

|

No-load voltage |

V |

60 |

||

|

Rated working voltage |

V |

18@TIG 26.4@MMA |

||

|

AC output frequency |

Hz |

20~250 |

||

|

AC balance |

% |

20~60 |

||

|

Background level |

A |

10~200 |

||

|

Pulse frequency |

Hz |

0.5~200 (DC) 0.5~25(AC) |

||

|

Pulse duty factor |

% |

5~95 |

||

|

Pre-flow time |

S |

0~5 |

||

|

Post-flow time |

S |

0~15 |

||

|

Rising time |

S |

0~15 |

||

|

Fall time |

S |

0~15 |

||

|

Remote control |

- |

Yes |

||

|

Arc start mode |

- |

HF arc starter |

||

|

Efficiency (%) |

% |

80 |

||

|

Duty cycle (%) |

% |

TIG: 200@25% - MMA: 160@25% |

||

|

Power factor |

- |

0.70 |

||

|

Type of cooling |

- |

Air cooled |

||

|

Working temperature range |

°C |

-10~+40 |

||

|

Storage temperature range |

°C |

-25~+55 |

||

|

Protection class |

- |

IP21S |

||

|

Insulation class |

- |

B |

||

Shipping Time

All orders are delivered within 10 business days unless delayed due to address verification issues or suspected fraudulent activity. We never ship during weekends or holidays. All shipments have real time tracking and verified tracking numbers so you can track your items 24/7 with delivery confirmation. Orders are shipped via UPS/USPS/Amazon Logistics. When shipped, orders will take 2-3 days to update tracking number. You will get a shipping confirmation once shipped.

We cannot be held accountable for the shipping carriers actions and cannot issue refunds for shipping charges for delayed packages.

If you have any questions or concerns about your order, please email us at support@arccaptain.com and our team will be happy to assist you, 7 days a week.

Please Note: We do not ship to Puerto Rico or Internationally. We do not ship to P.O. BOX addresses and/or APO or FPO addresses.

Delivery is unavailable to Yukon (YT), Northwest Territories (NT), Nunavut (NU), and Newfoundland and Labrador (NL) in Canada. In addition, delivery may be unavailable to certain remote or rural areas. If your shipping address is affected, we will contact you before shipment to confirm delivery availability or arrange a refund if delivery is not possible.

In the United States, we currently do not deliver to Hawaii, Alaska, Puerto Rico, or Guam. Please ensure that your shipping address is not located in these regions before placing an order.

Shipping

At ARCCAPTAIN, it’s our mission to provide quality welding equipment at genuinely affordable prices to welders everywhere. To do this, we work with manufacturers across the world and use a global distribution network to get you the goods for less.

Your equipment may be coming from the US, or Hong Kong, depending on the equipment purchased. Your specific delivery date will depend on the dispatch country and delivery address.

When will I receive my order?

Most items are usually shipped within 5-10 working days.

We do recommend allowing up to 3 weeks for your order in peak times, such as a special offer or promotion. Delivery times are beyond our control but rest assured that we only work with reliable welding manufacturers and suppliers to give you the best service.

How do I track my order?

Your delivery confirmation email will contain your tracking number and order details.

Taxes and other charges

Depending on the country of delivery, you may be required to pay extra tax or charges such as VAT and/or import duties.

Orders Delayed, Lost, Stolen Or Damaged

ARCCAPTAIN is not responsible for late, lost, stolen, damaged packages.

Any order shipped and shown delivered through the courier will be considered delivered and will not be refunded, re-shipped or replaced.

We will do everything we can to assist with the tracking of your order, however, here are the rules:

- Any order shipped and shown delivered through the courier will be considered delivered and will not be refunded, re-shipped or replaced.

- We cannot be held accountable for the shipping carriers actions and cannot issue refunds for shipping charges for delayed packages.

- We cannot guarantee the performance of any carrier and cannot accept responsibility for any carriers delays, packages delivered to incorrect addresses, and/or lost, stolen or damaged packages or products.

- If your package is delivered to an incorrect address, it is lost, stolen or damaged you need to file a claim direct with the courier.

Shipping Terms and Conditions

All orders MUST be shipped to the delivery address on your order. We cannot change the shipping address in your transaction to any other address after purchase. It is your responsibility to make sure your information is accurate when placing an order. Any mailing address mistakes on your part are not the responsibility of At ARCCAPTAIN.

Any orders with fraud alerts will not be shipped until all details and information are verified. No exceptions. We have a fraud prevention system to protect every party.

Fraud Prevention

ARCCAPTAIN is Level 1 PCI DSS compliant and 100% safe and secure for online payment processing. We work diligently to protect the safety and security of our customers and our assets.

All orders are at our discretion to be checked for fraudulent activity on varying levels of research. If we are unable to verify your payment through the information you have provided, we will communicate what is needed for us to move forward with the order process. Additional information, including but not limited to, a current photo ID, professional beauty license, passport or payment details may be requested

Why Arccaptain is the Best Choice?

36% increase in arc initiation efficiency

Multifunctional AC DC TIG welder

Packed with essential features, this machine excels at aluminum welding — outperforming comparable models by 36%.

Large LED Display

Easily adjust settings for any welding mode. Get clear data without removing your helmet.

AC DC PULSE WELDER

Pulse function helps you weld thin plates more easily

³/₆₄ inch to ¼ inch thickness

Capable of welding a variety of metal materials, it's a professional welder's tool of choice.

TIG SPOT WELDING

This ac dc TIG welder also features TIG spot welding capabilities.

Outstanding stick welding function

Equipped with outstanding stick welding function.

A Powerful Tool for Professional Welders

Best product ever! Highly recommend.

Best BUDGET AC/DC TIG Welder

Easily repair your car, cost-effective machine

Best product ever! Highly recommend.

Multi Process Aluminum Welding Machine