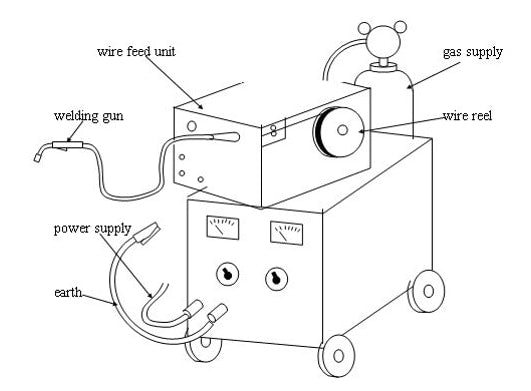

A MIG welder parts diagram shows each component and its role, helping you fix issues or upgrade your welder.

It includes the power source, wire feeder, welding gun, shielding gas, and grounding cable. The power source activates welding, the wire feeder moves the welding wire to the gun, and the gun melts the wire to join metals. Shielding gas protects the weld, and the grounding cable completes the circuit.

Understanding these parts through the diagram enables you to manage your welder effectively, quickly solve problems, and improve your work.

Keep reading and check out the MIG welder parts diagram to enhance your welding skills.

Overview of MIG Welder Parts

A MIG welder, also known as a Metal Inert Gas welder, is a type of welding machine that uses a spool of wire to create an electrical arc that melts and joins two pieces of metal together. MIG welding is a popular welding technique used in various industries, including automotive, construction, and manufacturing.

MIG Welding Advantages

MIG welding has several advantages over other types of welding. It is a fast and efficient welding technique that can be used on a variety of metals, including aluminum, steel, and stainless steel. MIG welding produces a clean and precise weld, making it ideal for welding thin materials.

MIG welding is a versatile welding technique that can be used for a variety of applications, including welding automotive parts, repairing machinery, and fabricating metal structures.

With the right equipment and training, you can become proficient in MIG welding and produce high-quality welds on a variety of metals.

Looking for the right equipment? Check out our affordable MIG welder collection for great options.

Key Components of a MIG Welder: An Illustrated Diagram of MIG Welder Parts

Photo grab from: https://www.en.hongky.com/mig-welding-equipment-and-principles

MIG welding is a popular welding process that is used to join metals together. The basic components of a MIG welder include a power source, a wire feeder, a welding gun, and a ground clamp.

The power source provides the electrical current needed to create the arc, while the wire feeder feeds the wire through the welding gun. The welding gun is used to direct the wire and create the arc, while the ground clamp is used to complete the electrical circuit.

1. Power Source

The power source is the heart of the MIG welder. It is responsible for generating the electrical current that is used to create the arc between the welding wire and the workpiece. The power source can be either a transformer or an inverter, and it is typically rated in amps.

2. Wire Feeder

The wire feeder is responsible for feeding the welding wire through the welding gun and into the weld pool. It consists of a motor, a drive roller, and a wire spool.

The wire feeder is controlled by the welding machine and can be adjusted to control the speed and amount of wire that is fed into the weld pool.

3. MIG Welding Gun

The welding gun is the part of the MIG welder that the welder holds and uses to create the arc between the welding wire and the workpiece. It consists of a trigger, a nozzle, and a contact tip.

The trigger controls the flow of electricity to the welding wire, while the nozzle and contact tip control the flow of shielding gas.

Need a new welding gun? Check out the best choices in our MIG welding gun collection.

4. Gas Regulator

The gas regulator is responsible for regulating the flow of shielding gas that is used to protect the weld pool from contamination. It consists of a pressure gauge, a regulator, and a flowmeter.

The pressure gauge measures the pressure of the gas in the cylinder, while the regulator and flowmeter control the flow of gas to the welding gun.

5. Ground Clamp

The ground clamp is responsible for connecting the workpiece to the welding machine. It consists of a clamp that is attached to the workpiece and a cable that is connected to the welding machine.

The ground clamp ensures that the electrical current flows through the workpiece and completes the welding circuit.

If you’re just starting out, get practical advice in our guide: MIG Welding Tips and Techniques For Beginners.

Common Accessories and Attachments for MIG Welders

When it comes to MIG welding, some various accessories and attachments can enhance the functionality of your MIG welder.

These accessories can help make your welding process easier, more efficient, and more precise. In this section, we will discuss some of the most common accessories and attachments for MIG welders.

Welding Wire: Most Essential Accessories for Mig Welding

One of the most essential accessories for MIG welding is the welding wire. Welding wire is the material that is used to create the weld. It is fed through the MIG gun and melted to form the weld. The welding wire comes in different sizes and materials, depending on the type of metal you are welding.

Another important accessory for MIG welding is the contact tip. The contact tip is the part of the MIG gun that comes into contact with the welding wire.

It is responsible for carrying the welding current to the wire and guiding it to the weld. The contact tip needs to be replaced periodically to ensure a smooth and consistent weld.

A wire feeder is another accessory that can be used to enhance the functionality of your MIG welder. The wire feeder is responsible for feeding the welding wire through the MIG gun.

It can be attached to the MIG welder or used as a separate unit. A wire feeder can help make the welding process more efficient and precise.

A shielding gas is another accessory that is commonly used in MIG welding. The shielding gas is used to protect the weld from contamination and oxidation. It is typically a mixture of argon and carbon dioxide. The shielding gas is fed through the MIG gun along with the welding wire.

Discover the best shielding gas by reading our guide: What is the Best Shielding Gas Used for MIG Welding?

Finally, a nozzle is an accessory that can be used to improve the quality of your weld. The nozzle is the part of the MIG gun that directs the shielding gas onto the weld. It can be made of different materials, such as copper or brass, and comes in different sizes and shapes. The nozzle needs to be cleaned and replaced periodically to ensure a clean and consistent weld.

Maintenance and Troubleshooting for MIG Welder Parts

Regular maintenance is vital to keep your MIG welder in optimal condition. Here are some maintenance tips to follow:

-

Keep the welder clean: Dust and debris can accumulate on the welder's surface, causing damage to internal parts. Use a soft cloth to clean the surface of the welder regularly.

-

Inspect the wire feed system: The wire feed system is one of the most critical components of a MIG welder. Check the wire feed rollers, guide tubes, and liner for any damage or wear and tear. Replace any damaged parts immediately.

-

Check the gas flow: The gas flow is essential for a quality weld. Make sure the gas cylinder is full and the regulator is set to the correct pressure. Check for any leaks or damage to the gas hose.

-

Inspect the gun liner: The gun liner is responsible for feeding the welding wire from the spool to the gun. Check the liner for any kinks or damage and replace it if necessary.

-

Replace the contact tip: The contact tip is responsible for transferring the welding current to the wire. Check the tip for any damage or wear and tear and replace it if necessary.

If you experience any issues with your MIG welder, refer to the parts diagram to identify the specific component causing the problem.

Here are some troubleshooting tips for common issues:

-

Poor weld quality: Check the wire feed system, gas flow, and contact tip. Make sure the wire is feeding correctly and the gas flow is set to the correct pressure. Replace the contact tip if necessary.

-

Burnback: Burnback occurs when the welding wire fuses to the contact tip. Check the wire feed system and make sure the wire is feeding correctly. Replace the contact tip if necessary.

-

Wire feed issues: Check the wire feed system for any kinks or damage. Make sure the wire is feeding correctly and the rollers are set to the correct tension.

How Do You Use a MIG Welder Step by Step?

If you are new to MIG welding, using a MIG welder for the first time may seem daunting. However, with proper guidance, you can learn how to use a MIG welder step by step. Here's a breakdown of the steps involved:

-

Prepare the Workpiece: Before you begin welding, ensure that the workpiece is clean and free of any rust, paint, or debris. This will help ensure a strong weld.

-

Set Up the Welder: Set up the MIG welder according to the manufacturer's instructions. This typically involves setting the wire feed speed and voltage to the appropriate levels for your workpiece.

-

Prepare the Wire: Thread the welding wire through the machine and into the welding gun. Ensure that the wire is properly seated in the rollers and the gun.

-

Put on Safety Gear: Put on your safety gear, including a welding helmet, gloves, and protective clothing.

-

Position the Gun: Position the welding gun at a 90-degree angle to the workpiece. Hold the gun with both hands and brace your arms against your body for stability.

-

Start Welding: Pull the trigger on the gun to start the flow of gas and wire. Move the gun slowly along the joint, maintaining a consistent distance from the workpiece. Continue welding until you have completed the joint.

-

Finish the Weld: Once you have completed the joint, release the trigger and wait for the wire to stop feeding. Allow the weld to cool before removing any clamps or fixtures.

Once you know your machine, dialing in the right settings is key. Check out our article on MIG Welding Wire Speed & Voltage Chart for guidance.

What Are the Three Advantages of MIG Welding?

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a welding process that offers several advantages over other welding techniques. Here are three main benefits of MIG welding:

-

High welding speed: MIG welding allows for fast and efficient welding, making it suitable for high-volume production. The process is automated, which means that the welder can focus on other tasks while the machine does the welding. This makes MIG welding a popular choice for industries that require high-speed production.

-

Versatility: MIG welding is one of the most versatile welding methods, as it can be done semi-automatically or fully automatically and on a variety of materials such as steel, stainless steel, cast iron, magnesium, and aluminum. This makes it a popular choice for industries that require welding on different materials.

-

High-quality welds: MIG welding produces high-quality welds with faster speed. During welding, the welder uses a welding torch to continuously feed a consumable heated wire electrode and shielding gas. The shielding gas protects the weld from atmospheric contamination, which results in clean, strong, and durable welds. This makes MIG welding a popular choice for industries that require high-quality welds.

Conclusion: MIG Welder Parts

Getting familiar with the MIG welder parts diagram is really helpful for using and maintaining your machine. The diagram gives you a clear look at where each part goes and what it does, making it much easier to spot and fix any issues.

Important parts like the wire feeder keep the welding wire moving smoothly, while the contact tip delivers the electrical current needed for a steady arc. You’ll also find components like the gas nozzle, diffuser, torch head, and power source, all of which play important roles.

By keeping these parts in good shape, you’ll enjoy better performance and more reliable welds.

Curious about other welding methods? Compare them all in MIG vs. TIG vs. Stick vs. Flux Core Welding Techniques.

Frequently Asked Questions on MIG Welder Parts Diagram

What are the parts of MIG welding?

MIG welding uses a welding gun that feeds a wire electrode into the welding pool. The wire electrode serves as a filler material that melts and fuses with the base metal.

The welding gun also emits a shielding gas that protects the weld from atmospheric contamination. A MIG welder typically consists of a power source, a wire feeder, a welding gun, and a gas cylinder.

What is inside a MIG welder?

Inside a MIG welder, you will find a transformer or an inverter that converts the input power to the appropriate welding voltage and current. The wire feeder is responsible for feeding the wire electrode from the spool to the welding gun.

The welding gun contains the contact tip, the nozzle, and the diffuser that control the wire electrode and the shielding gas. The gas cylinder contains the shielding gas that protects the weld from atmospheric contamination.

What does a MIG welder need?

To operate a MIG welder, you will need a power source, a wire feeder, a welding gun, a gas cylinder, and a wire electrode. You will also need the appropriate safety gear, including a welding helmet, welding gloves, and protective clothing.

What kind of gas do you use with a MIG welder?

MIG welding typically uses a mixture of argon and carbon dioxide or pure argon as the shielding gas. The choice of shielding gas depends on the type of metal being welded and the welding conditions.

How do you reset a MIG Welder?

To reset a MIG welder, you need to turn off the power source, unplug the machine, and wait for a few minutes. This will allow the capacitors to discharge and reset the machine. You should also check the wire feed system, the gas flow, and the grounding connection to ensure that they are functioning properly.

What is the hole at the end of a MIG weld?

The hole at the end of a MIG weld is called a crater or crater crack. It forms when the weld pool cools and contracts too quickly, often because the arc is stopped abruptly, leaving a small void or depression at the end of the weld.