Choosing the best welding rod for beginners plays a major role in how quickly new welders develop confidence and control. The right welding rod makes it easier to strike an arc, maintain a stable weld puddle, and produce clean, consistent welds.

Beginners who start with the wrong rod often struggle with sticking, excessive spatter, and uneven beads, which slows progress and leads to frustration.

Learning what welding rod to use early helps reduce mistakes and wasted materials.

What Are Welding Rods?

Welding rods, also known as electrodes, are metal sticks coated with flux that conduct electrical current and create the welding arc.

As the rod melts, it fills the joint between metals while the flux coating protects the molten weld from contamination. Once the weld cools, the flux forms slag that can be removed to reveal the finished bead.

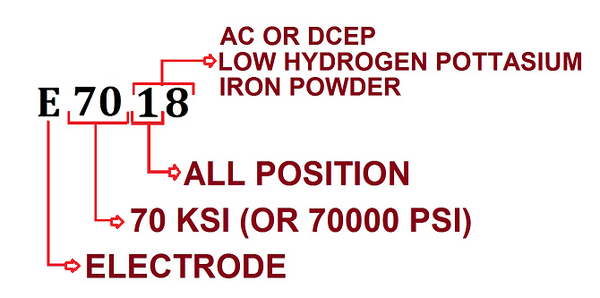

Welding electrodes used in stick welding are classified under AWS A5.1, which defines their strength, welding position capability, and flux composition.

📌 Also read: Welding Rod Types Explained: How To Choose the Right One

What to Consider When Choosing the Best Welding Rod for Beginners

Selecting the right welding rod becomes easier when beginners focus on a few core factors that directly affect learning and weld quality.

Base Metal Properties

- The rod must match the type of metal being welded

- Mild steel is the most beginner‑friendly material

Welding Current

- Some welding rods require DC only

- Beginner‑friendly rods often support both AC and DC machines

Using a stable, entry level stick welder helps beginners maintain consistent heat. ArcCaptain welding machines are designed with smooth output control, which makes learning arc length and puddle control easier.

Base Metal Thickness

- Thinner metals are easier to control with smaller rod diameters

- Thicker metals require higher heat and more experience

Welding Position

Beginner welding rods should perform well in:

- Flat

- Horizontal

- Vertical

- Overhead positions

Skill Level

The best welding rod for beginners should:

- Strike easily

- Restart smoothly

- Remain stable despite inconsistent hand movement

📌 Also read: What Welding Rod Should You Use For Your Project? Factors to Consider

Common Types of Welding Rods and Their Applications

Understanding common welding rods helps beginners avoid starting with electrodes that are too advanced.

|

Welding Rod |

Key Characteristics |

Beginner Suitability |

|---|---|---|

|

6010 |

Deep penetration, fast freezing slag (DC+) |

Poor |

|

6011 |

Works on AC/DC, aggressive arc |

Fair |

|

6013 |

Smooth arc, easy slag removal |

Excellent |

|

7018 |

High strength, low‑hydrogen, moisture sensitive |

Poor |

Why 6013 Is the Best Welding Rod for Beginners

Most welding schools introduce students to welding using 6013 rods because of their forgiving behavior. The arc is smooth and predictable, allowing beginners to focus on controlling the puddle rather than fighting unstable heat.

The slower freezing slag gives learners more time to adjust hand movement and travel speed, making it easier to build muscle memory and confidence before progressing to more demanding rods.

📌 Also read: 6013 vs. 7018: How To Decide for Your Next Weld

How to Stick Weld with the Best Welding Rod for Beginners

Learning proper stick welding technique is essential, even when using a beginner‑friendly rod. Start by cleaning the metal surface to ensure a stable arc starts.

Learning proper stick welding technique is essential, even when using a beginner‑friendly rod. Start by cleaning the metal surface to ensure a stable arc starts.

Strike the arc by lightly tapping the rod and lifting slightly to maintain a short arc length. Move the rod steadily while watching the weld puddle instead of the arc itself.

Reliable accessories improve consistency during practice. ArcCaptain welding clamps, electrode holders, and safety gear help beginners maintain better control and positioning while learning basic stick welding techniques.

Beginners should practice straight bead welds before attempting weaving motions. When using a 6013 rod correctly, the finished weld will appear smooth and slightly raised once the slag cools and separates.

Common 6013 Welding Problems Beginners Face and How to Fix Them

Mistakes are part of the learning process, but most beginner issues have simple solutions.

Welding Rod Keeps Sticking

- Amperage is set too low

- Arc length is too short

Too Much Spatter

- Amperage is too high

- Travel speed is inconsistent

Slag Does Not Peel Off Easily

- Base metal is dirty

- Rod angle is incorrect

Uneven Weld Beads

- Travel speed changes frequently

Consistent amperage control from a dependable welding machine reduces many of these problems. Beginner focused welders from ArcCaptain provide stable output that helps limit sticking and spatter.

Check These ArcCaptain Products You Can Shop

Explore MoreBest Amperage Settings for the Best Welding Rod for Beginners

Correct amperage settings make welding easier and more forgiving for beginners. Starting near the middle of the recommended range allows room for small adjustments.

Note: Actual amperage requirements vary depending on the welding machine, joint design, material thickness, and welding position. Always fine‑tune settings based on arc behavior and weld appearance.

|

6013 Rod Size |

Recommended Amperage Range |

|---|---|

|

3/32 inch |

70–90 amps |

|

1/8 inch |

90–130 amps |

If the rod sticks, slightly increase the amperage. If excessive spatter or burn‑through occurs, reduce the heat.

What a Good Weld Looks Like When Using the Best Welding Rod for Beginners

A properly executed weld using a beginner welding rod will have an even width, a smooth surface, and no deep undercut along the edges.

Once cooled, the slag should peel off easily, revealing a clean and uniform bead. Learning to visually inspect weld quality helps beginners correct mistakes faster.

Wearing a clear, properly rated welding helmet improves visibility during inspection. ArcCaptain welding helmets offer reliable lens clarity for both practice and inspection.

6013 vs 7018: Which Welding Rod Is Better for Beginners?

|

Feature |

6013 |

7018 |

|---|---|---|

|

Arc Stability |

Smooth and forgiving |

Stable but less forgiving |

|

Ease of Use |

Beginner‑friendly |

Intermediate to advanced |

|

Storage Requirements |

Minimal |

Requires dry storage |

|

Best Use Case |

Learning and light fabrication |

Structural welding |

For beginners, 6013 is the better starting point.

6011 vs 7018: Which Is Easier to Weld?

|

Feature |

6011 |

7018 |

|---|---|---|

|

Arc Behavior |

Aggressive |

Smooth but demanding |

|

Machine Compatibility |

AC/DC |

Primarily DC |

|

Beginner Difficulty |

Moderate |

High |

Neither rod is ideal for first‑time welders compared to 6013, but 6011 is generally easier than 7018.

📌Also read: Top 7018 Welding Rod Uses & Best Techniques

Best Welding Rod for Beginners for Mild Steel Projects

Mild steel is commonly used for beginner welding projects because it is affordable, forgiving, and easy to work with.

For home repairs, small fabrications, and practice welds, 6013 remains the best welding rod for beginners due to its versatility and ease of control.

Pairing the right rod with a reliable stick welder, such as those offered by ArcCaptain, improves learning consistency.

Common Mistakes Beginners Make When Choosing Welding Rods

- Starting with high‑skill welding rods too early

- Choosing rod sizes that are too thick

- Ignoring welding position limitations

- Welding incompatible metals

Check These ArcCaptain Products You Can Shop

Explore MoreConclusion

Choosing the best welding rod for beginners makes learning to weld faster, easier, and more enjoyable.

The 6013 welding rod stands out because it offers smooth arc starts, stable puddle control, and clean weld results on mild steel.

Starting with the right welding rod allows beginners to focus on technique and skill development, building a strong foundation for more advanced welding applications in the future.

Frequently Asked Questions About the Best Welding Rod for Beginners

Which is better, 6013 or 7018?

6013 is better for beginners because it is easier to strike, more forgiving, and simpler to control. While 7018 produces stronger welds, it requires more skill and proper storage, which makes it less suitable for beginners.

Is 6011 or 7018 easier to weld?

6011 is generally easier than 7018, but it still has a more aggressive arc than 6013. Most beginners find 6013 the easiest rod to learn with.

What is a 6013 welding rod good for?

A 6013 welding rod is commonly used for mild steel, home repairs, general fabrication, and projects that require welding in multiple positions.

Why use 6010 or 7018?

6010 rods are used for deep penetration applications like pipe welding, while 7018 rods are used for strong structural welds. Both require more experience than beginner‑friendly rods.

Is 6010 better than 6013?

6010 is not better for beginners. It has a more aggressive arc and requires faster, more precise technique. 6013 is smoother and more forgiving for learning.