Welding fixtures are essential tools that bring consistency and accuracy to metalworking. These devices hold metal parts in the correct position during welding, ensuring every weld is straight, strong, and repeatable.

From automotive assembly lines to home workshops, welding fixtures transform challenging tasks into reliable, high-quality results.

Curious how welding fixtures can improve your projects? Read on to discover the core principles, types, and technical details behind these vital welding aids.

What Are Welding Fixtures?

Welding fixtures are mechanical devices designed to position and secure workpieces for welding.

By keeping parts stable and precisely aligned, they eliminate guesswork and allow welders to focus on creating strong joints.

Whether working with steel beams or intricate sheet metal, fixtures provide the foundation for professional-quality welds.

The importance of welding fixtures lies in their ability to boost both productivity and quality. They minimize human error, reduce the risk of warping, and support repeatable results across multiple parts. In any setting where precision matters, welding fixtures are a must-have.

Types of Welding Fixtures

Welding fixtures come in several styles, each designed to meet specific needs. Understanding the differences helps you choose the right fixture for your job.

Basic Welding Fixtures

Basic welding fixtures rely on clamps, stops, and pins to hold metal parts in place. These fixtures are straightforward and suitable for low-volume or custom work.

They are commonly used in repair shops and DIY projects where flexibility is more important than speed.

Modular Welding Fixtures

Modular welding fixtures use standardized parts such as plates, clamps, and locating pins that can be assembled in many configurations.

This adaptability makes them ideal for workshops handling a variety of projects. Modular systems save time and reduce the need for specialized fixtures for every new job.

Custom Welding Fixtures

Custom welding fixtures are built for specific applications. Designed to fit unique part geometries and welding requirements, they deliver maximum accuracy and efficiency.

Automotive and aerospace industries often use custom fixtures to meet strict quality standards.

Welding Fixtures vs. Welding Jigs

While both fixtures and jigs support welding, fixtures focus on holding parts steady, while jigs may also guide the welding tool. Fixtures are preferred when stability and repeatability are critical.

Core Components of Welding Fixtures

Every welding fixture is made up of important parts that work together to keep your project steady. Knowing these components helps you understand how fixtures achieve accuracy.

- Fixture Base: The sturdy platform that supports the entire setup.

- Clamps and Stops: Devices that grip and secure parts in place.

- Locating Pins: Pins that ensure parts are positioned accurately.

- Adjustable Arms: Components that adapt to different part sizes and shapes.

- Magnets and Positioners: Tools for holding metal at specific angles or in hard-to-reach spots.

Each component contributes to the overall reliability and precision of the welding fixture.

Applications of Welding Fixtures

Welding fixtures are used in many different fields, from large factories to small garages. Their versatility makes them valuable for a wide range of tasks.

Automotive Welding Fixtures

In automotive manufacturing, welding fixtures enable fast, repeatable assembly of car bodies and frames. These fixtures hold large panels and structural parts in precise alignment, supporting robotic and manual welding.

Industrial and Aerospace Welding Fixtures

Factories and aerospace shops depend on welding fixtures for accuracy and safety. Fixtures help meet strict tolerances and ensure every part meets performance standards.

📌 For more on advanced welding techniques, check out this expert guide to increasing deposition rate in welding.

DIY and Home Welding Fixtures

Home welders use basic fixtures such as clamps and magnets to hold parts steady for repairs or creative builds. Even simple setups can dramatically improve weld quality and safety.

3D Printing and Prototyping

Welding fixtures also play a role in 3D printing and rapid prototyping, holding printed metal parts for post-processing or final assembly.

Choosing the Right Welding Fixture for Your Project

Selecting the best welding fixture means thinking about your materials, the size of your project, and your welding method. Making the right choice ensures your work is both efficient and accurate.

- Material: Consider the type and thickness of metal.

- Size and Shape: Match the fixture to your workpiece dimensions.

- Welding Process: Fixtures should support your chosen method, such as MIG, TIG, or stick welding.

- Project Volume: For high-volume production, modular or custom fixtures offer efficiency.

Choosing the correct fixture ensures smooth workflow and consistent results.

📌 Want to master different welding methods? Don’t forget to check out this guide on how to arc weld.

Materials Used in Welding Fixtures

The material you choose for your welding fixture affects its strength, weight, and ability to handle heat. Each option has its own advantages.

Steel, Aluminum, and Cast Iron

Most welding fixtures are made from steel, aluminum, or cast iron. Steel is the most popular due to its strength and ability to withstand high temperatures.

Cast iron offers excellent stability and resists warping, making it ideal for heavy-duty fixtures. Aluminum is lighter and easier to handle but less durable under intense heat.

Heat Resistance and Wear

Welding generates significant heat, so fixture materials must resist thermal distortion. Steel and cast iron excel in this area, while aluminum is suitable for lighter-duty tasks.

Non-Metallic Fixtures

In some cases, non-metallic materials like ceramics or composites are used, especially when electrical insulation or chemical resistance is needed.

Designing and Building a Welding Fixture

Designing a welding fixture starts with careful planning and ends with thorough testing. Following these steps helps ensure your fixture works as intended.

Step 1: Define the Purpose

Start by analyzing the welding process and the parts to be joined. Identify critical dimensions, alignment requirements, and access points for the welding torch.

Step 2: Sketch and Measure

Draw a detailed plan of the fixture, marking where clamps, pins, and stops will be placed. Accurate measurements are essential for proper fit and function.

Step 3: Assemble and Test

Build the fixture using strong, heat-resistant materials. Test the setup with actual workpieces, making adjustments to ensure stability and accessibility.

Step 4: Fine-Tune for Efficiency

Refine the fixture for quick loading and unloading. Modular designs allow for easy changes between projects.

📌 Ready to explore welding with different metals? Discover tips on how to weld magnesium.

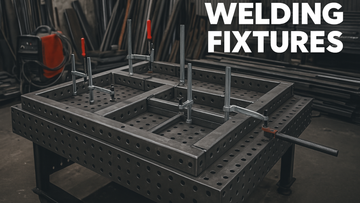

Welding Fixture Tables

A welding fixture table gives you a flat, sturdy surface to set up your projects. These tables make it easy to position and clamp your work for accurate, repeatable results.

Welding fixture tables are robust, flat surfaces engineered for accurate setup. Their grid of holes or slots allows for flexible placement of clamps and pins.

These tables are especially valuable for large or complex assemblies, providing a stable base for repeatable, high-quality welds.

When choosing a fixture table, look for:

- Flatness and strength

- Multiple mounting points for clamps and pins

- Adjustable legs or wheels for mobility

A quality welding fixture table is a long-term investment for any serious welder.

Best Practices for Using Welding Fixtures

Using welding fixtures correctly helps you get the best results and keeps your work safe. Follow these best practices to make the most of your fixtures.

- Safety First: Always secure both the fixture and workpieces before welding.

- Prevent Warping: Use enough clamps and supports to minimize movement from heat.

- Quick Changes: Modular fixtures speed up setup for different projects.

- Regular Checks: Inspect fixtures for wear or damage before each use.

Browse new fixture setups and tips to keep your welding safe and efficient.

Maintenance and Care for Welding Fixtures

Taking care of your welding fixtures ensures they last longer and work properly every time. Simple maintenance steps can make a big difference.

- Clean fixtures after each use to remove spatter and debris.

- Store them in a dry environment to prevent rust.

- Inspect moving parts and replace worn components as needed.

- Well-maintained fixtures deliver consistent results project after project.

Final Thoughts

Welding fixtures are the backbone of precise, efficient welding. They hold parts steady, improve safety, and ensure every weld meets high standards.

Whether you’re building cars, airplanes, or home projects, the right fixture makes all the difference. Integrate welding fixtures into your workflow to achieve professional results every time.

For more helpful guides and tips about welding, don’t forget to check out Arccaptain.

And if you’re looking for high-quality welding machines, equipment, accessories, and more welding tools, browse and shop at Arccaptain to find everything you need for your next project.

You May Shop

|

|

Arccaptain MIG205 Pro Gas MIG Welder Stainless Steel Multi Process Machine |

Arccaptain AC DC TIG200P Multi Process Pulse TIG Aluminum Welder |

Frequently Asked Questions About Welding Fixtures

What are fixtures in welding?

Fixtures in welding are devices that hold metal pieces in the correct position during welding. They keep parts steady and aligned, making it easier to create strong, accurate welds. Using fixtures helps reduce mistakes and improves the quality of the finished product.

What is an example of a welding fixture?

A common example of a welding fixture is a metal clamp that holds two steel bars at a right angle. More advanced fixtures might use adjustable arms and pins to hold several pieces at once. These setups ensure all parts stay exactly where they need to be while welding.

What is the best material for weld fixtures?

Steel is usually the best material for weld fixtures because it is strong, durable, and resists heat. Cast iron is also popular for its stability and resistance to warping. Aluminum can be used for lighter jobs, but it doesn’t handle heat as well as steel or cast iron.

How to design a weld fixture?

To design a weld fixture, start by deciding how your parts should be held and aligned. Sketch out where you need clamps, pins, and supports. Build the fixture from strong, heat-resistant materials, and test it with your workpieces to make sure everything fits and stays in place.