Choosing between 10 gauge vs 12 gauge wire can seem confusing at first, but it’s one of the most important decisions when working with electrical or welding projects. The right wire size keeps your circuits safe, efficient, and long-lasting.

Want to understand exactly which wire is right for your needs? Read on to learn the key differences, when to use each, and how to make the best choice for your setup.

Understanding Wire Gauge and Why It Matters

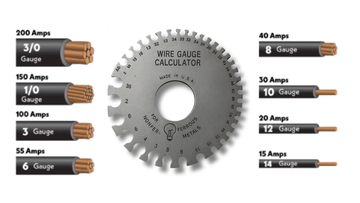

Wire gauge refers to the thickness of the wire and is measured using the American Wire Gauge (AWG) system. In this system, the smaller the number, the thicker the wire. That means a 10 gauge wire is thicker than a 12 gauge wire.

Thicker wires carry more current with less resistance and heat buildup. This makes gauge selection critical for safety and efficiency in both home and shop applications.

This guide focuses on copper wire, which is the most common type used in homes. Aluminum wire has different ampacity ratings and should always follow NEC-specific guidelines.

10 Gauge vs 12 Gauge Wire: The Key Differences

When comparing 10 gauge vs 12 gauge wire, the main differences come down to thickness, ampacity, flexibility, and cost.

|

Feature |

10 Gauge Wire |

12 Gauge Wire |

|---|---|---|

|

Diameter |

Thicker (2.588 mm) |

Thinner (2.053 mm) |

|

Ampacity |

Up to 30 amps |

Up to 20 amps |

|

Resistance |

Lower |

Higher |

|

Flexibility |

Stiffer |

Easier to bend |

|

Cost |

More expensive |

More affordable |

According to the National Electrical Code (NEC) Table 310.16, 10 gauge copper wire is typically rated for 30 amps, and 12 gauge copper wire for 20 amps when used in 60°C-rated circuits such as NM-B cable.

A 10 gauge wire can handle more current and longer distances without overheating, while a 12 gauge wire is easier to work with for everyday circuits.

When to Use 10 Gauge Wire

If you’re powering heavy-duty equipment or running long wire lengths, 10 gauge wire is your best bet. It’s ideal for appliances like water heaters, dryers, air conditioners, or welders that draw a lot of current.

Because it’s thicker, it resists voltage drop better over long distances. However, it’s less flexible and can be harder to install in tight spaces.

📌 For projects that require controlling wire feed and voltage precisely, check out the article MIG Welding Wire Speed and Voltage Chart to better understand how wire and voltage work together in welding applications.

When to Use 12 Gauge Wire

A 12 gauge wire is perfect for standard household circuits and light-duty uses. It’s commonly used for outlets, lights, and small appliances that draw up to 20 amps.

It’s easier to bend, strip, and install, making it a great choice for most indoor wiring jobs. If your circuit doesn’t require high current or long runs, 12 gauge wire is usually the most practical and cost-effective option.

📌 Want to learn how wire thickness affects your welding results? Don’t forget to read How to MIG Weld Metals of Different Thicknesses for helpful insights on adjusting to various metal thicknesses.

10 Gauge vs 12 Gauge Wire: Ampacity and Distance Guide

Ampacity measures how much electrical current a wire can safely carry. Here’s a quick reference for choosing between 10 and 12 gauge wires based on current and distance:

|

Circuit Type |

Recommended Gauge |

Max Distance (ft) |

Amps |

|---|---|---|---|

|

Standard Outlet |

12 AWG |

50 |

20A |

|

Heavy Appliance |

10 AWG |

100 |

30A |

|

Long Outdoor Run |

10 AWG |

150 |

25A |

If your wire run is long or your device draws a lot of power, go with the thicker 10 gauge wire to prevent voltage drop and overheating.

Voltage drop calculations can vary slightly depending on the wire material, temperature, and load type, so always verify using the NEC or a voltage drop calculator for precise results.

What Happens If You Use the Wrong Wire Gauge

Using the wrong wire gauge can cause serious problems. If the wire is too thin for the current load, it can overheat, melt insulation, or even start a fire.

On the other hand, using a wire that’s too thick isn’t dangerous but can make installation harder and cost more.

Always match the wire gauge to your circuit’s amperage rating and check your local electrical codes before starting any wiring project.

10 Gauge vs 12 Gauge Extension Cords

Extension cords also follow the same gauge rules. A 10 gauge extension cord is thicker and can handle more power, making it ideal for tools like welders, compressors, and generators.

A 12 gauge cord works fine for most household tools like drills or saws, but if you’re running equipment that draws more amps or needs a longer cord, 10 gauge is the safer choice.

Check Related Products

📌 Need help choosing the right wire for your welding setup? Browse MIG Wire Sizes: How to Choose the Right Wire for Your Project to understand how wire diameter affects performance and weld quality.

How to Tell If a Wire Is 10 Gauge or 12 Gauge

Telling wire sizes apart is simple if you know what to look for:

- Check the markings on the wire’s insulation. It usually lists the gauge (e.g., “10 AWG” or “12 AWG”).

- Use a wire gauge tool to measure the diameter.

- Compare visually if you have samples. A 10 gauge wire looks noticeably thicker than a 12 gauge wire.

10/2 Wire vs 12/2 Wire: What’s the Difference?

The “/2” in wire labeling means the cable has two insulated conductors plus a ground wire.

A 10/2 wire is thicker and can handle 30 amps, while a 12/2 wire is rated for 20 amps. Both are used for single-phase circuits, but 10/2 is better suited for heavy-duty appliances and long runs.

Which Wire Gauge Is Stronger and Better Overall

A 10 gauge wire is physically stronger and can carry more current, but that doesn’t always make it the better choice. The right wire depends on your specific project.

For short household runs, 12 gauge is more practical. For high-power or long-distance circuits, 10 gauge is safer and more efficient. Always base your decision on load requirements and circuit length.

Cost and Practical Considerations

Cost is another factor when comparing 10 gauge vs 12 gauge wire. Thicker wire uses more copper, so it costs more per foot. It’s also stiffer, which makes installation trickier in tight spaces.

If your project doesn’t require the extra power capacity, 12 gauge wire can save you time and money without sacrificing safety.

Wires with higher temperature ratings (like THHN insulation) can safely carry slightly more current than NM-B cables, but always follow the labeling and NEC tables for your specific wire type.

Safety Tips When Choosing Between 10 Gauge and 12 Gauge Wire

- Always match wire gauge to the circuit breaker’s amperage rating.

- Never mix different gauges on the same circuit.

- Follow local electrical codes for all installations.

- When in doubt, consult a licensed electrician to confirm your wire size.

The National Electrical Code (NEC) and the Electrical Safety Foundation International (ESFI) both recommend matching wire gauge to circuit breaker size and never mixing gauges on the same circuit. These steps help prevent overheating and ensure long-term reliability.

Conclusion

Understanding the difference between 10 gauge vs 12 gauge wire helps you make safer and smarter electrical choices.

Use 12 gauge for standard circuits and 10 gauge for heavy-duty or long-distance wiring. Always consider amperage, distance, and safety codes before starting any project.

For more helpful guides and tips about wire gauges, welding, and electrical projects, visit ArcCaptain. They offer high-quality welding machines, tools, gears and accessories designed to make every welding or wiring project easier and safer.

Frequently Asked Questions About 10 Gauge vs 12 Gauge Wire

Is 10 gauge thicker than 12 gauge?

Yes, 10 gauge wire is thicker than 12 gauge wire. Thicker wires carry more current safely and have lower electrical resistance. This makes 10 gauge wire ideal for high-power applications, while 12 gauge is used for general household circuits.

Should I use 12 or 10 gauge wire?

Use 12 gauge wire for standard 20-amp circuits like outlets and lights. Choose 10 gauge wire for 30-amp circuits or long runs where voltage drop could be a concern. Always base your choice on the amperage and distance of the circuit.

What happens if a wire gauge is too big?

If a wire is too big for the circuit, it won’t cause damage, but it can be harder to install and cost more. The wire might not fit easily into connectors or outlets. It’s best to use the correct gauge for efficiency and convenience.

What is the difference between 12/2 wire and 10/2 wire?

Both 12/2 and 10/2 wires have two insulated conductors and a ground wire. The difference is in thickness and current capacity. 12/2 handles 20 amps, while 10/2 handles 30 amps, making it better for larger appliances.

Which is heavier, 10 gauge or 12 gauge wire?

A 10 gauge wire is heavier because it contains more copper. This extra material allows it to carry more current and stay cooler under load. The added weight also makes it slightly harder to handle during installation.