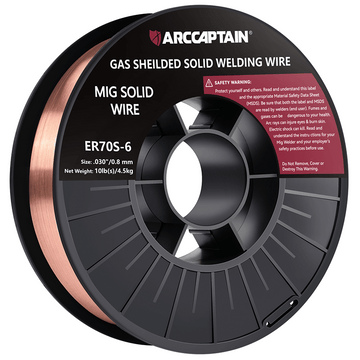

Mild Steel MIG Wire

- En vedette

- Meilleures ventes

- Alphabétique, de A à Z

- Alphabétique, de Z à A

- Prix: faible à élevé

- Prix: élevé à faible

- Date, de la plus ancienne à la plus récente

- Date, de la plus récente à la plus ancienne

Craft your next masterpiece or tackle that high-stakes project with ArcCaptain's wire welders, your ideal companions for aluminum and all your welding endeavors.

Renowned for their precision and efficiency, these welders are perfectly supplemented by our mild steel MIG wire, tailored to overcome the intricate demands of welding, ensuring robust, flawless welds with each application. Combine this with a MIG welder from our collection for an unbeatable welding experience.

Don't forget that a complete welding solution includes top-to-bottom protection. Explore our welding protective gear, robust welding gloves, and innovative welding helmets to ensure you're optimally outfitted for all your welding projects.

Experience Superb Welding with Our Quality Mild Steel MIG Wire

Elevate your welding with our top-grade mild steel MIG wire:

Consistent Performance

Benefit from our wire's uniform quality and adherence to industry standards, delivering consistent strength and outstanding weld integrity.

TÜV Tested and Approved

Our welding wire has passed rigorous testing and earned TÜV certification, guaranteeing high-quality welds with minimal impurities due to optimal deoxidization.

For precision work, consider pairing with our TIG welders, which offer remarkable control and accuracy.

Smooth Weld Appearance

Achieve a smooth and aesthetically pleasing weld bead with minimal post-weld cleanup, thanks to the wire's superb wetting properties.

Excellent Arc Characteristics

Enjoy reduced spatter and a cleaner weld area with our MIG wire, which provides excellent arc stability for a refined welding performance.

Top off your protective ensemble with a top-notch welding helmet to guard your face and eyes.

Versatility and Ease of Use

Suitable for novices and experts alike, our mild steel MIG wire is user-friendly, ensuring precise control for strong, durable welds across various applications.

Don't forget to shield your head with a quality welding cap to complete your gear.

Immerse yourself in our curated collection and trust the ArcCaptain commitment to delivering safety, practicality, and lasting quality in every product.

Related Articles To Read

- Common Wire Feed Welding Issues and How To Solve Them

- Different Types of MIG Welding Wire - Explained

Frequently Asked Questions

What wire is best for MIG welding mild metal?

For MIG welding mild steel, ER70S-6 wire is widely regarded as one of the best options due to its high tensile strength, superior welding properties, and compatibility with a variety of mild steel grades. Its blend of manganese and silicon deoxidizers assists in producing clean and sound welds.

Does mild steel MIG wire need gas?

Yes, mild steel MIG wire requires a shielding gas to protect the weld pool from contamination by the surrounding air. Common gases used with mild steel MIG wire include a mix of Argon and Carbon Dioxide or pure CO2. The gas prevents oxidation and ensures a stronger and cleaner weld.

What is mild steel welding wire used for?

Mild steel welding wire is commonly used for general-purpose welding, repairing, and fabricating mild steel materials. Its applications span a wide range of industries, from automotive repair to construction and industrial fabrication, due to its versatility and strong bond with mild steel components.

Can you weld stainless with mild steel MIG wire?

While it is technically possible to weld stainless steel with mild steel MIG wire, it is not recommended because the weld will not have the same corrosion resistance properties as stainless steel, potentially leading to premature rusting or failure of the weld joint. It is best to use stainless steel wire for welding stainless steel materials to maintain the integrity and properties of the metal.