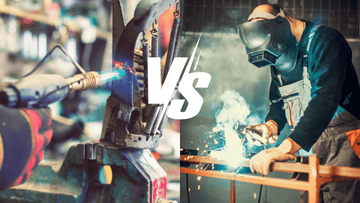

Brazing vs welding? Well, Those two are popular methods. Both methods have their advantages and disadvantages, and choosing the right one depends on various factors such as the metals being joined, the joint design, and the application.

Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal.

Welding, on the other hand, involves melting the base metals to create a fusion between them. The heat source can be an electric arc, a laser, or a gas flame.

In this article, we will explore the differences between brazing and welding and help you decide which method is best for your project.

Understanding Brazing and Welding

What is Brazing?

Brazing is a metal-joining process that involves the use of a filler metal, which is heated above its melting point and then distributed between two or more close-fitting parts by capillary action. The filler metal is then cooled and solidified, forming a strong, permanent bond between the parts. Brazing is a versatile process that can be used to join a wide range of metals, including copper, brass, bronze, steel, and aluminum.

Learn How to Braze Aluminum: A Step-by-Step Guide in this detailed guide.

Advantages of Brazing

One of the key advantages of brazing is that it can be used to join dissimilar metals, such as copper and steel. This is because the filler metal used in brazing has a lower melting point than the base metals being joined, which means that the base metals do not need to be melted. This is in contrast to welding, where the base metals are melted and fused together.

Definition of Welding

Welding is a metal-joining process that involves the use of heat to melt and fuse two or more pieces of metal together. The welding process can be used to join similar or dissimilar metals, and it is commonly used in the construction of buildings, bridges, and other structures.

The welding process typically involves the use of a filler metal, which is melted along with the base metals being joined. The heat required for welding is typically generated by an electric arc, a gas flame, or a laser. Welding can produce strong, durable joints that are capable of withstanding high stresses and strains.

Key Differences Between Brazing and Welding

One of the key differences between brazing and welding is the temperature required for each process. Brazing typically requires a lower temperature than welding, which means that there is less risk of distortion or damage to the base metals being joined. Welding, on the other hand, requires a higher temperature, which can result in distortion or damage to the base metals if not properly controlled.

In terms of filler metal, brazing typically uses a filler metal that has a lower melting point than the base metals being joined. This allows the filler metal to flow into the joint by capillary action, creating a strong, permanent bond. Welding, on the other hand, typically uses a filler metal that has a similar melting point to the base metals being joined, which allows the filler metal to be melted along with the base metals to create a fusion bond.

When deciding between brazing and welding, it is important to understand the key differences between these two processes.

Here are some of the main differences:

1. Temperature Range

One of the most significant differences between brazing and welding is the temperature range used in each process. Brazing typically uses a lower heat than welding, usually below the melting points of the base metals but above those of the filler metal. Welding, on the other hand, uses a much higher temperature, often melting the base metals together.

2. Joint Types

Another key difference between brazing and welding is the type of joint that is formed. In welding, the joint is formed by melting the two pieces together, resulting in a very strong bond. Brazing, on the other hand, does not melt the two pieces together. Instead, a filler metal is placed between the two pieces, which then melts and forms a bond. This type of joint is generally not as strong as a welded joint, but it can still be very effective for many applications.

3. Material Compatibility

The materials being joined also play a significant role in determining whether brazing or welding is the best choice. Brazing is typically used for joining dissimilar metals or metals with different melting points. Welding, on the other hand, is better suited for joining similar metals.

4. Mechanical Strength

Mechanical strength in welding typically produces a stronger joint than brazing. The joints made with welding will be just as strong as the base metals and often even stronger than its base metals. On the other hand, in brazing, the joints are usually only as strong as the filler metal, and while those joints aren't weak by any means, the joints in welding are still stronger.

Advantages of Welding Over Brazing

Welding offers several advantages over brazing. Welding produces joints that are just as strong as the base metals and often even stronger than the base metals. On the other hand, brazing joints are usually only as strong as the filler metal, and while those joints aren't weak by any means, the joints in welding are still stronger.

- Welding is also better suited for parts that require durability. The joints made with welding can withstand higher stress and strain than brazed joints. Welding is also more suitable for materials that are thicker or require more strength. Brazing, on the other hand, is better suited for thinner materials.

- Another advantage of welding is that it can be used to join dissimilar metals with different melting points. Welding can also be used to join metals with different thicknesses. Brazing, on the other hand, is limited in its ability to join dissimilar metals.

- Welding is a more versatile method for joining metals than brazing. Welding can be used to join a wide range of metals, including aluminum, stainless steel, and titanium. Brazing, on the other hand, is limited to joining metals that have similar melting points.

Advantages of Brazing Over Welding

When it comes to joining metals, there are several methods to choose from. Among these methods, brazing and welding are two of the most popular options. While welding is commonly used for its strength and durability, brazing offers several advantages over welding in specific applications.

- One of the most significant advantages of brazing over welding is that it allows for the joining of dissimilar metals with different melting points. This is because the base metals do not need to be melted, reducing the risk of material distortion or metallurgical changes. In contrast, welding requires the melting of base metals, which can lead to changes in the material properties.

- Brazing is also suitable for complex assemblies and thin-walled sections. This is because brazing requires less heat than welding, which reduces the risk of warping or distortion. In addition, brazing is a versatile method for joining dissimilar metals, which makes it ideal for complex assemblies that require different types of metals.

- Another advantage of brazing over welding is that it is easier to learn and requires less skill. Brazing operators can usually acquire brazing skills faster than welding skills. This is because brazing requires less precision and synchronization of heat application and deposition of filler metal.

Choosing Between Brazing and Welding for Your Project

When deciding between brazing and welding for your project, there are several factors to consider. Here are some tips to help you make the right choice:

1. Material Compatibility

Brazing is a great option for joining dissimilar metals that cannot be welded together. This is because brazing uses a filler metal that has a lower melting point than the base metals being joined. Welding, on the other hand, requires that the base metals being joined have similar melting points.

2. Joint Strength

If you need a joint that will withstand high stress, welding is the better option. Welding melts the base metals, resulting in a very strong joint. Brazing, on the other hand, uses a filler metal that may not be as strong as the base metals being joined.

3. Equipment Available

If you don't have access to welding equipment, brazing may be the better option. Brazing requires less heat than welding, so it can be done with a simple torch. Welding, on the other hand, requires more specialized equipment, such as a welding machine.

4. Project Requirements

When deciding between brazing and welding, it's important to consider the specific requirements of your project. For example, if you need to join parts that have complex shapes, brazing may be the better option. Brazing is also a good option for mass production, as it can be done quickly and efficiently.

5. Cost Considerations

Finally, you should consider the cost of each option. In general, brazing is a more cost-effective option than welding. Brazing requires less specialized equipment and can be done more quickly, which can save you money in the long run.

Safety Considerations in Brazing and Welding

When performing brazing and welding operations, it is important to consider certain safety measures to ensure the safety of everyone involved. Here are some important safety considerations when performing brazing and welding operations:

1. Protective Gear

When brazing or welding, it is important to wear protective gear to protect yourself from the heat and sparks that are produced during the process. The following protective gear should be worn:

- Welding helmet or mask with a shaded lens to protect your eyes and face from the bright light produced during the process

- Welding gloves to protect your hands from the heat and sparks

- Flame-resistant clothing to protect your body from the heat and sparks

- Respirator or other breathing protection to protect your lungs from harmful fumes and gases

2. Ventilation

Good ventilation is important when performing brazing or welding operations to prevent the buildup of harmful fumes and gases. The following steps should be taken to ensure proper ventilation:

- Work in a well-ventilated area with good air flow

- Use ventilating fans and exhaust hoods to carry all fumes and gases away from work

- Use air-supplied respirators as required

3. Cleanliness

Before brazing or welding, it is important to clean the base metals thoroughly to prevent any surface contaminants from interfering with the brazing or welding process. Any surface contaminant of unknown composition on base metals may add to the fume hazard and may cause inadequate alloy bonding.

4. Training

It is important to receive proper training before performing brazing or welding operations. Improper use of equipment or lack of knowledge of safety measures can lead to serious injury or even death. Make sure you are properly trained and qualified to perform brazing or welding operations before attempting any work.

Learning Brazing and Welding Skills

If you want to learn brazing and welding skills, there are several ways to do so. Some of the most popular methods include formal education, apprenticeships, and DIY resources.

1. Formal Education

Formal education is a great way to learn brazing and welding skills. Many community colleges and vocational schools offer courses in welding and brazing. These courses typically cover the basics of welding and brazing, including safety, equipment, and techniques. Some courses may also cover more advanced topics, such as metallurgy and welding engineering.

2. Apprenticeships

Another way to learn brazing and welding skills is through an apprenticeship program. These programs typically involve working under the guidance of a skilled welder or brazer. Apprenticeships can be a great way to learn hands-on skills and gain real-world experience. Many apprenticeships also offer classroom instruction in addition to on-the-job training.

3. DIY Resources

If you prefer to learn on your own, there are many DIY resources available. Websites, books, and videos can all be great sources of information. Some websites even offer free online courses in welding and brazing. DIY resources can be a great way to learn at your own pace and on your own schedule.

No matter which method you choose, it's important to practice your brazing and welding skills regularly. The more you practice, the better you'll become. With time and dedication, you can become a skilled welder or brazer.

Conclusion

In conclusion, choosing between brazing and welding depends on your specific needs. Both methods have their advantages and disadvantages, and it is essential to understand the differences between them to make an informed decision.

Brazing is a popular method in metal fabrication that uses a filler metal to join two or more materials. It is suitable for joining dissimilar metals and can preserve the integrity of the base metals. Brazing requires less heat than welding and can be used to join materials with different thicknesses.

Welding involves the fusion of base metals to create strong and durable joints suitable for various industries. It allows for the joining of different metals, provides high strength, and finds extensive use in structural applications. Welding requires more heat than brazing and can be used to join materials with similar thicknesses.

When choosing between brazing and welding, consider the materials you are working with, the joint strength required, and the application of the finished product. If you need a strong, durable joint, welding may be the better option. However, if you need to join dissimilar metals or materials with different thicknesses, brazing may be the more appropriate choice.

Frequently Asked Questions

Is Brazing as Strong as Welding?

Brazing joints are usually only as strong as the filler metal used, while welding joints are typically as strong as the base metals or even stronger. However, brazing can still create strong joints that are suitable for many applications.

Is Brazing Just Soldering?

No, brazing is not the same as soldering. While both processes involve joining two pieces of metal, they use different techniques and materials. Brazing involves heating the base metals to a high temperature and melting a filler metal into the joint, while soldering uses a lower temperature and a different type of filler metal.

What is Brazing Used for?

Brazing is used in a variety of industries and applications, including automotive, aerospace, plumbing, and jewelry making. It is commonly used to join dissimilar metals, repair metal parts, and create strong and durable joints.

Why Choose Brazing Over Welding?

Brazing can be a better choice than welding in certain situations. For example, brazing can join dissimilar metals, which is difficult or impossible with welding. Brazing also requires less heat than welding, which can prevent distortion or damage to the base metals. Additionally, brazing is suitable for mass production and complex designs.

When Should Braze Welding Not Be Used?

Braze welding may not be the best choice for certain applications. For example, if the joint will be subjected to high stress or high temperatures, welding may be a better option. Additionally, if the base metals are not clean or properly prepared, the brazing joint may not be strong or durable.