TIG welding basics involve using a tungsten electrode to produce a precise, clean weld that is ideal for thin materials and detailed work.

TIG welding requires a bit more skill than other types of welding, but it's worth it if you want to create high-quality welds with minimal spatter and distortion.

It's also a great choice if you need to weld thin materials or if you need to create welds that are aesthetically pleasing.

In this article, we'll cover the TIG welding basics, including the equipment you'll need, the types of metals you can weld, and the techniques you'll need to master.

Whether you're a beginner or an experienced welder, this guide will give you the knowledge you need to get started with TIG welding.

What is TIG Welding?

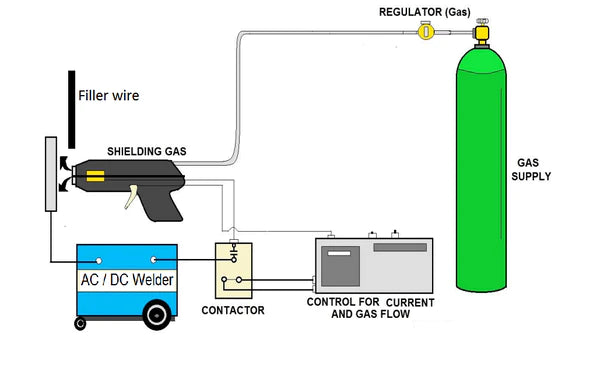

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a welding process that uses a non-consumable tungsten electrode to produce a weld. The weld area is protected from atmospheric contamination by an inert shielding gas, typically argon.

TIG welding differs from other types of welding, such as MIG or stick welding, in that it uses a non-consumable electrode, meaning the electrode does not get consumed during the welding process.

Instead, the electrode is used to create the arc which melts the base material and filler material (if used) to form the weld.

TIG welding is a highly precise and versatile process that can be used to weld a wide range of materials, including aluminum, stainless steel, and titanium. It is particularly useful for welding thin materials, as it allows for precise control of the heat input and minimizes distortion.

Equipment Needed for TIG Welding

To get started with TIG welding, you'll need to have the following essential equipment:

-

Power Supply: The power supply is the heart of your TIG welding setup. It provides the electrical energy to create the welding arc. TIG welding machines come in different types, including constant current (CC), AC, DC+, DC-, or AC/DC. Choose one that suits your specific welding needs.

-

TIG Torch: The TIG torch holds the tungsten electrode and allows the welder to control the arc. It's important to choose a torch that is comfortable to hold and easy to maneuver. The torch should also be compatible with your power supply.

-

Tungsten Electrodes: Tungsten electrodes are non-consumable and come in various sizes and shapes. They are used to create the welding arc and transfer the current to the workpiece. The size and type of tungsten electrode you choose will depend on the thickness and type of metal you're welding.

-

Shielding Gas: TIG welding requires a shielding gas to protect the weld from atmospheric contamination. Argon is the most commonly used shielding gas for TIG welding. The gas is stored in a cylinder and regulated by a flowmeter.

In addition to the above, you may also need the following equipment:

-

Filler Rod: Filler rod is used to add material to the weld joint. It's important to choose a filler rod that is compatible with the base metal you're welding.

-

Foot Pedal: A foot pedal allows you to control the amperage of the welding arc with your foot. This can be useful for maintaining a consistent weld.

-

Ground Clamp: A ground clamp is used to connect the workpiece to the welding machine. It ensures a stable electrical connection and helps prevent electrical shock.

Advantages of TIG welding

One of the key advantages of TIG welding is its ability to produce high-quality welds with minimal spatter and fumes.

This makes it a popular choice for applications where cleanliness and aesthetics are important, such as in the food and beverage industry, aerospace, and motorsports.

TIG welding is a widely used welding process that offers several advantages over other welding techniques. Some of the advantages of TIG welding are:

-

Clean and Precise Welds: TIG welding produces clean and precise welds, making it a popular choice for welding jobs in industries such as aerospace, food equipment, high-purity processing, and motorsports. The process allows for better control over the weld pool, resulting in a neater and more aesthetically pleasing weld.

-

Versatility: TIG welding can be used to weld a wide range of materials, including aluminum, stainless steel, nickel alloys, and titanium. This versatility makes it a popular choice for welding jobs that require welding of dissimilar metals.

-

No Spatter: TIG welding produces no spatter, which means that there is no need for post-weld cleaning. This saves time and reduces the risk of contamination.

-

No Fumes: TIG welding produces no fumes, which makes it a safer choice for welding jobs in confined spaces or poorly ventilated areas.

-

No Flux Required: TIG welding does not require any flux, which means that there is no need to remove any slag after welding. This saves time and reduces the risk of contamination.

-

High-Quality Welds: TIG welding produces high-quality welds that are free from defects such as porosity, undercutting, and incomplete fusion. This makes it a popular choice for welding jobs that require high-quality welds.

Understanding TIG Welding Electrodes

TIG welding electrodes play an essential role in the welding process. They conduct the welding current to the workpiece and create an arc that melts the metal to be welded.

The electrode also adds filler material to the weld joint. In TIG welding, there are two types of electrodes: tungsten and non-tungsten electrodes.

1. Tungsten Electrodes

Tungsten electrodes are the most commonly used electrodes in TIG welding. They are made of tungsten and have a high melting point, which allows them to withstand the high temperatures generated during welding.

Tungsten electrodes come in different types, including pure tungsten, thoriated tungsten, ceriated tungsten, and lanthanated tungsten.

Type of Tungsten Electrode Explained

Each type of tungsten electrode has a different composition and is suitable for specific welding applications. For instance, pure tungsten electrodes are used for welding aluminum and magnesium alloys, while thoriated tungsten electrodes are used for welding steel and stainless steel.

Tungsten electrodes also come in different sizes, ranging from 0.5mm to 6.4mm. The size of the electrode you choose depends on the thickness of the metal you are welding. A general rule of thumb is to use an electrode that is 1.5 times the thickness of the metal being welded.

2. Non-Tungsten Electrodes

Non-tungsten electrodes are made of materials other than tungsten. They are used for welding non-conductive materials such as ceramics, glass, and quartz. Non-tungsten electrodes come in different types, including carbon electrodes, zirconiated electrodes, and rare earth electrodes.

Carbon Electrodes

Carbon electrodes are made of graphite and are used for welding non-conductive materials. Zirconiated electrodes are made of zirconium and are used for welding aluminum and magnesium alloys. Rare earth electrodes are made of a mixture of rare earth oxides and are used for welding stainless steel and nickel alloys.

The TIG Welding Process Explained

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a welding process that uses a non-consumable tungsten electrode to produce a weld on a workpiece. It is a versatile process that can be used to weld a wide range of materials, including aluminum, stainless steel, and copper alloys.

Step-by-Step Guide

Here is a step-by-step guide to the TIG welding process:

-

Preparing the Metal: Before starting the TIG welding process, the metal must be cleaned and prepared. This involves removing any rust, dirt, or oil from the surface of the metal. The metal should be cleaned using a wire brush or sandpaper.

-

Setting Up the Welding Equipment: The TIG welding equipment must be set up before starting the welding process. This involves connecting the TIG torch to the welding machine, setting the amperage, and selecting the appropriate tungsten electrode.

-

Striking the Arc: Once the metal is cleaned and the equipment is set up, you can start the welding process. To start the arc, you need to touch the tungsten electrode to the metal and lift it slightly to create an arc. This arc generates the heat required to melt the metal and create the weld.

-

Adding Filler Metal: As you weld, you will need to add filler metal to the joint. The filler metal is added using a filler rod that is fed into the weld pool. The filler metal should be added in a consistent manner to ensure a strong weld.

-

Finishing the Weld: Once the welding is complete, the weld should be cleaned and inspected. The weld should be cleaned using a wire brush or grinder to remove any slag or debris. The weld should also be inspected for any defects or cracks.

Common TIG Welding Techniques

When it comes to TIG welding, there are several techniques that you should be familiar with to ensure a successful weld. Here are some of the most common TIG welding techniques:

1. Welding in Various Positions

TIG welding can be done in various positions, including flat, horizontal, vertical, and overhead. Each position requires different techniques and adjustments to the welding parameters. For example, welding overhead requires a lower amperage and a shorter arc length to prevent the molten weld pool from falling.

2. Controlling the Heat Input

Controlling the heat input is crucial to achieving a high-quality weld. Too much heat can cause the metal to warp or even melt, while too little heat can result in a weak weld. To control the heat input, you can adjust the amperage, the travel speed, and the distance between the torch and the workpiece.

3. Managing the Filler Rod

The filler rod is used to add material to the weld pool and create a strong bond between the two pieces of metal. Managing the filler rod is important to ensure a consistent and even weld. You should feed the filler rod into the weld pool at a steady rate and maintain a consistent distance between the rod and the torch.

Beginner's Tips for Improving Your TIG Welding Skills

If you're new to TIG welding, it can be overwhelming to know where to start. But with some practice and the right equipment setup, you can improve your TIG welding skills in no time. Here are some tips to get you started:

-

Practice, practice, practice: The key to improving your TIG welding skills is to practice as much as possible. Start with simple projects and work your way up to more complex ones. The more you practice, the more comfortable you will become with the process.

-

Proper equipment setup: Make sure your TIG welding equipment is set up correctly. This includes having the right type of tungsten electrode, using the correct gas flow rate, and having the right amperage setting for the thickness of the metal you are welding. Check your equipment before each use to ensure everything is in working order.

-

Use the right filler material: Using the correct filler material is important for creating strong, uniform welds. Use a filler material that is the same type of metal as the base metal you are welding. For example, if you are welding aluminum, use an aluminum filler material.

-

Keep your workspace clean: TIG welding is not tolerant of any contaminants. Make sure your workspace is clean and free of any debris or oils. Use a good degreaser to clean your base metal before you scrub it with a dedicated wire brush.

-

Continuous learning: TIG welding is a skill that takes time to master. Keep learning and improving your technique by reading articles, watching videos, and taking classes. The more you learn, the better you will become.

TIG Welder Setup Explained

Setting up a TIG welder may seem daunting at first, but with a bit of guidance, it can be done quickly and easily. Here are some steps to follow when setting up your TIG welder:

-

Check and Connect Power Supply: Make sure that your TIG welder is connected to a suitable power supply. Check the manufacturer's instructions for the correct voltage and amperage settings.

-

Connect Gas Supply: Connect the gas supply to the TIG welder. The gas used in TIG welding is typically argon, but other gases can be used depending on the material being welded. Check the manufacturer's instructions for the correct gas flow rate.

-

Connect Ground Clamp: Connect the ground clamp to the workpiece. This will complete the electrical circuit and allow the TIG welder to function.

-

Instal Tungsten Electrode: Install the tungsten electrode into the TIG torch. The diameter of the electrode will depend on the thickness of the material being welded. Check the manufacturer's instructions for the correct size and type of tungsten electrode to use.

-

Setup Torch: Set up the TIG torch according to the manufacturer's instructions. This will typically involve installing the collet, collet body, and nozzle.

-

Set Welding Settings: Set the welding amperage and gas flow rate according to the manufacturer's instructions. This will vary depending on the material being welded and the thickness of the material.

-

Conduct Test Weld: Before beginning your project, it is recommended to do a test weld on a scrap piece of material. This will allow you to adjust your settings and ensure that your TIG welder is functioning properly.

Conclusion

In conclusion, TIG welding is a precise and versatile process that can produce clean, precise, and aesthetically pleasing welds on a wide range of base materials. It is a good process for critical welds like those found in aerospace, food and beverage equipment, high-purity processing, and motorsports.

To successfully practice TIG welding, you need to have proper equipment, techniques, and safety measures in place. It is essential to maintain a steady arc length and arc speed and keep the arc length at a consistent distance away from the metal being welded.

Some other essential points to keep in mind when TIG welding include:

- Use the correct polarity for the material being welded.

- Use the correct tungsten electrode for the application.

- Clean the base material thoroughly before welding.

- Use filler metal that matches the base material.

- Use proper shielding gas to protect the weld from contamination.

Ready to start TIG welding? Explore our top-quality TIG machines at ArcCaptain and add your preferred model to your cart. For further assistance, feel free to contact us today!

Frequently Asked Questions

What is the Basic Principle of TIG Welding?

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is a welding process that uses a non-consumable tungsten electrode to produce the weld. In this process, an electric arc is created between the tungsten electrode and the workpiece, which melts the metal and forms a weld pool. The weld pool is protected from atmospheric contamination by a shielding gas, usually argon or helium.

Can I Learn TIG Welding on My Own?

Yes, you can learn TIG welding on your own, but it is recommended to take a course or training program to learn the basics. TIG welding requires a good amount of skill, patience, and practice to master. It is important to learn the correct techniques and safety procedures to avoid any accidents or injuries. There are many resources available online, such as tutorials and videos, that can help you get started.

Which is Stronger Mig or Tig Welding?

Both MIG and TIG welding are strong and reliable welding processes, but the strength of the weld depends on various factors, such as the type of material being welded, the welding technique, and the quality of the weld. TIG welding is usually preferred for welding thinner materials and producing high-quality, precise welds, while MIG welding is preferred for welding thicker materials and producing faster welds.

What are the Basic Settings for TIG Welding Aluminum?

The basic settings for TIG welding aluminum include selecting the correct tungsten electrode, adjusting the amperage and gas flow rate, and using the correct filler rod. The tungsten electrode should be a pure tungsten or a tungsten alloy with a low percentage of thorium or zirconium. The amperage should be set to a low level to prevent burning through the material, and the gas flow rate should be adjusted to ensure proper shielding. The filler rod should be the same as the base material or a compatible alloy. It is important to clean the material thoroughly before welding to ensure a strong, clean weld.